Produktgruppe

Carbon filter

A carbon filter is made from activated charcoal, which is microporous coal produced by charcoal either by physical or chemical activation. The coal can then be used for various cleaning processes. The shape of the charcoal after activation differs according to the purpose for which it is to be used.

Since activated charcoal is really good at absorbing bad odours in the environments they are placed, it is obvious to use it to clean the air that enters houses and buildings from the outside.

The life of a carbon filter varies greatly depending on the amount of air and gases it absorbs. It is therefore necessary that you observe any changes in the air quality after a few months.

Vil du have et uforpligtende tilbud?

Send dine oplysninger til os, så kontakter vi dig inden for 24 timer (alle hverdage).

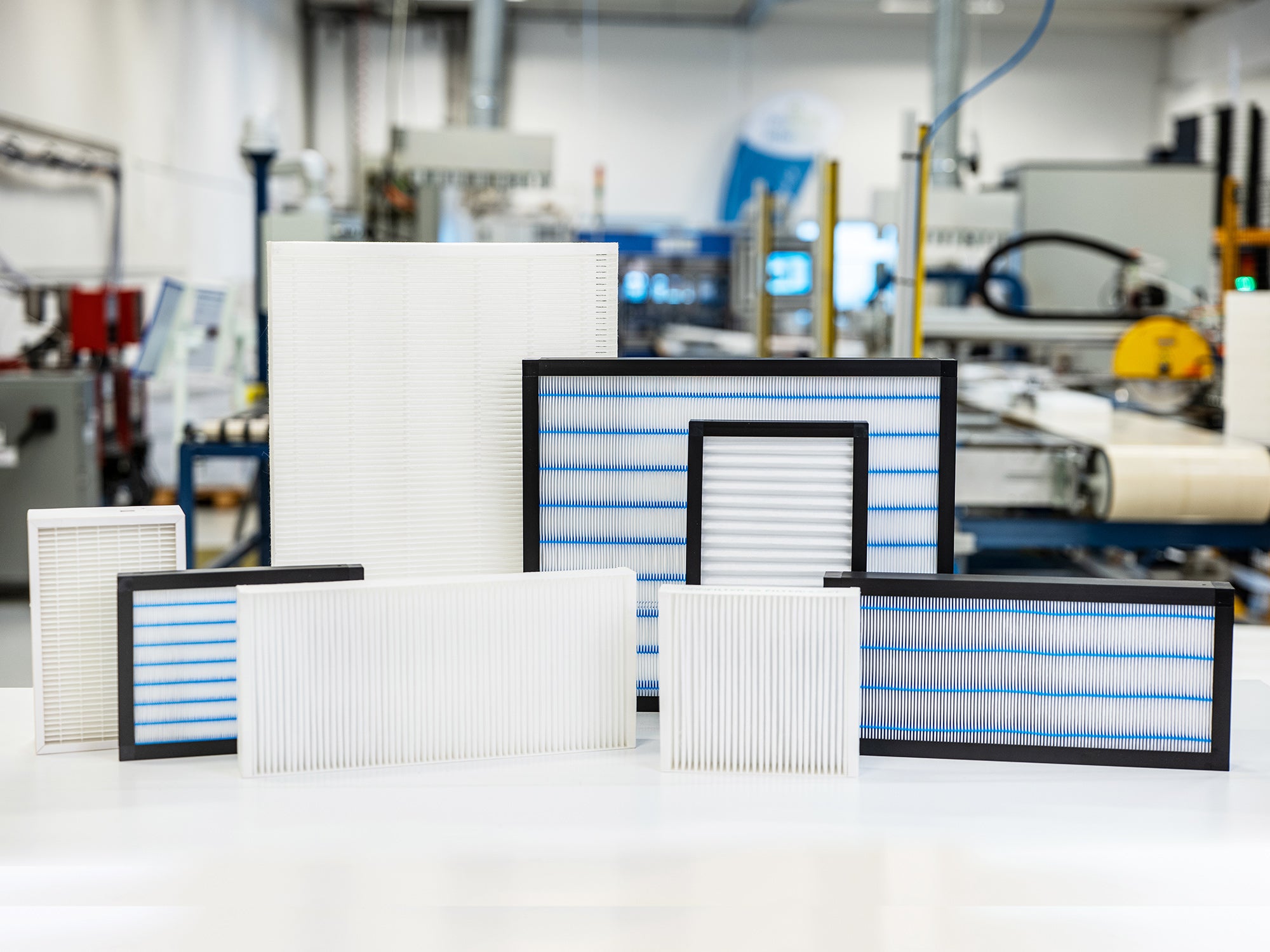

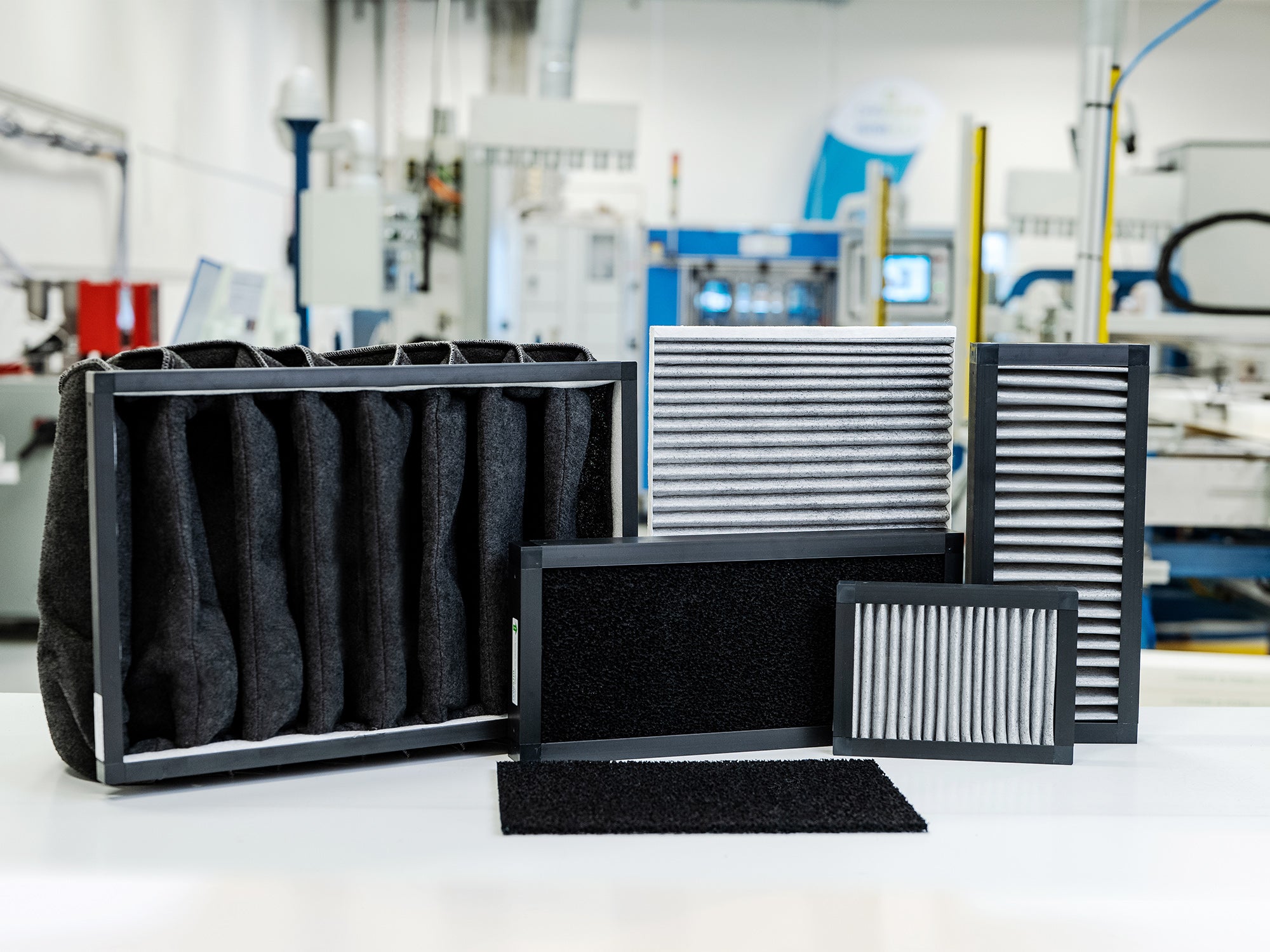

Production of carbon filters

Our carbon filters are manufactured at our own factory in Denmark. Carbon filters are activated charcoal constructed as either mats or in a sturdy frame containing activated charcoal pieces / cubes. Each cube contains 100% activated charcoal and has a size of 48x48 mm and 676 outlets per unit cell. A typical filter consists of 40-60 cubes - so 676 outlets per cube provides a total of 27-40,000 outlets. This gives the carbon filter an extremely large surface area and high density within the plastic frame.

It is important to keep in mind that a carbon filter is meant to complement an existing granular filter in the ventilation system.

The carbon filter is mounted on after the primary granular filter, as this first filters particles like dust. The carbon filter layer will then absorb any odours that may be in the air.

Advantages

- Absorbs odours

- High quality

- Large filter area

- Durable

- Reduces the intake of damaging air particles

+45 49 19 22 66

Mandag - torsdag: kl. 8.00 - 15.00

Fredag: kl. 9.00 - 13.00

info@danfilter.dk

Svartid: Ca. 24 timer på hverdage

Kontor og weblager

DANFILTER ApS - CVR: 10062527

Farum Gydevej 75, 3520 Farum, DK

Lagerafhentning

Mandag - torsdag: kl. 8.00 - 16.00

Fredag: kl. 8.00 - 14.00