ISO 16890 - test og dokumentation af filtre

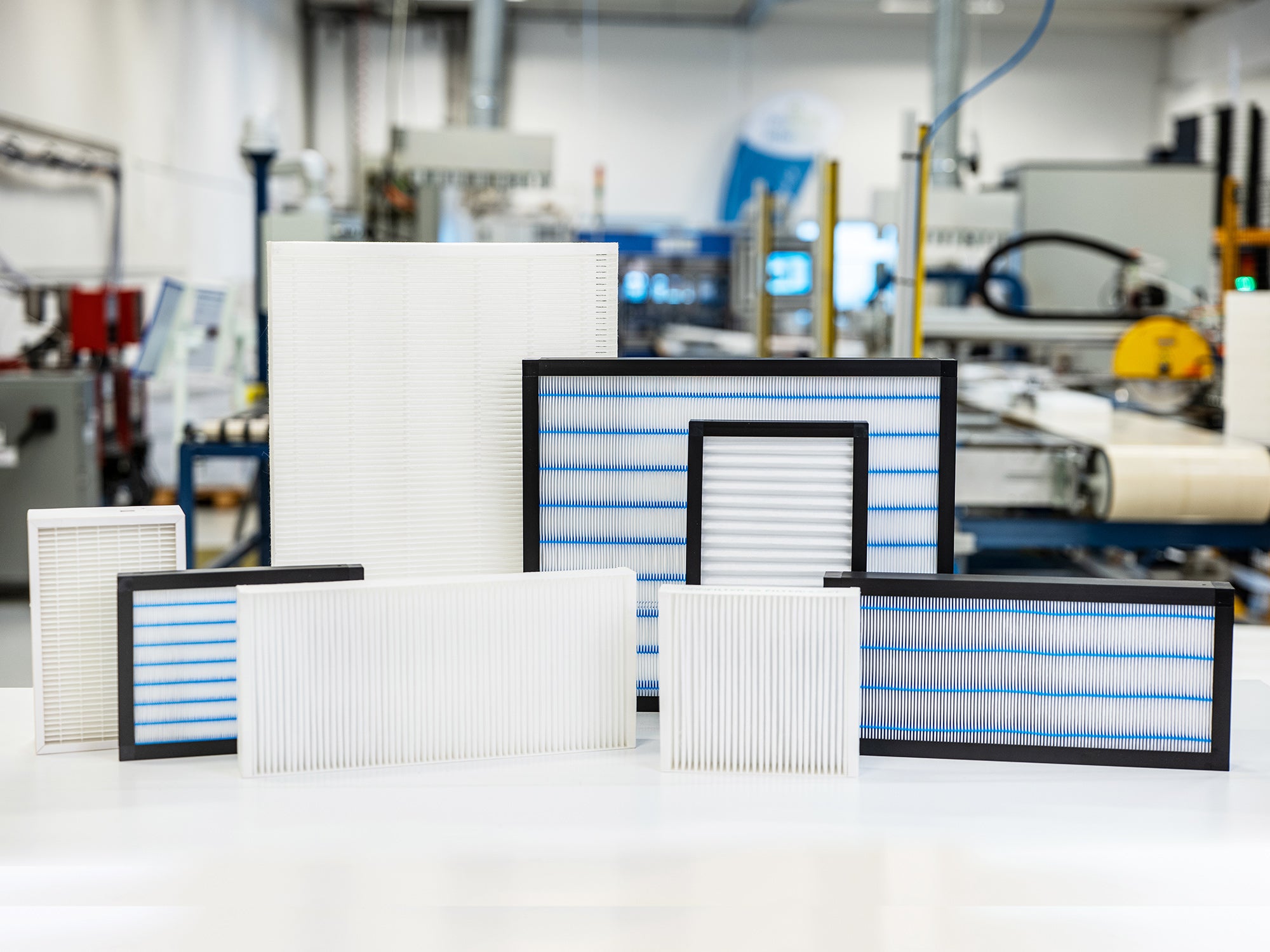

Hos Danfilter tester og dokumenterer vi vores produkter. Dette sker naturligvis i henhold til de gældende standarder i branchen. Den internationale standard, ISO 16890, kom til i 2017-2018 og erstatter den tidligere europæiske standard EN779:2012. Alle filterklasser har derfor fået nye betegnelser i henhold til ISO-standarden. De gamle betegnelser er dog ikke forsvundet og vil stadig være at finde på Danfilters produkter sammen med de nye betegnelser.

Herunder giver vi dig et overblik over ISO 16890 og EN779:2012. Har du spørgsmål til vores specifikationer eller filterstandarder, er du velkommen til at kontakte vores serviceteam indenfor teknisk rådgivning.

ISO 16890 – Ny international norm for test af filtre

Med ISO 16890 har vi altså fået en ny metode til at teste og dokumentere vores filtre på. Med den gamle standard EN779:2012 blev alle filtre testet med partikler i samme størrelse, 0,4 µm. Dengang afgjorde en partikeltælling før og efter testen filterets effektivitet, og filteret blev efterfølgende klassificeret i filterklasserne G3, G4, M5, M6, F7, F8 og F9.

Den nye standard, ISO 16890, er en mere præcis metode til at vurdere et filters evne til at fjerne partikler fra luften. I stedet for de generelle klasser baseres ISO 16890-klassificeringen

på filterets effektivitet overfor partikelstørrelserne GROV, PM10, PM2.5 og PM1. Ved ISO 16890 ligger fokus altså på at optimere filtreringsevnen indenfor forskellige partikelstørrelser (10 µm, 2,5 µm og 1 µm). Du får dermed et bedre dokumenteret filter end ved den tidligere standard EN779:2012.

| Designation | EN779:2012 | ISO 16890 |

| Standard Filter | G4 or M5 | ePM 10 >50% |

| Pollen Filter | F7 | ePM 2,5 65-80% / ePM 1,0 50-65% |

| SafeAir Filter | F9 or higher | ePM 2,5 >95% / ePM 1,0 >80% |

ISO 16890 – Ny international norm for test af filtre

Med ISO 16890 har vi altså fået en ny metode til at teste og dokumentere vores filtre på. Med den gamle standard EN779:2012 blev alle filtre testet med partikler i samme størrelse, 0,4 µm. Dengang afgjorde en partikeltælling før og efter testen filterets effektivitet, og filteret blev efterfølgende klassificeret i filterklasserne G3, G4, M5, M6, F7, F8 og F9.

Den nye standard, ISO 16890, er en mere præcis metode til at vurdere et filters evne til at fjerne partikler fra luften. I stedet for de generelle klasser baseres ISO 16890-klassificeringen

på filterets effektivitet overfor partikelstørrelserne GROV, PM10, PM2.5 og PM1. Ved ISO 16890 ligger fokus altså på at optimere filtreringsevnen indenfor forskellige partikelstørrelser (10 µm, 2,5 µm og 1 µm). Du får dermed et bedre dokumenteret filter end ved den tidligere standard EN779:2012.

| Designation | EN779:2012 | ISO 16890 |

| Standard Filter | G4 or M5 | ePM 10 >50% |

| Pollen Filter | F7 | ePM 2,5 65-80% / ePM 1,0 50-65% |

| SafeAir Filter | F9 or higher | ePM 2,5 >95% / ePM 1,0 >80% |

Fordele ved at teste filtre efter den nye ISO 16890 standard

Det er en stor fordel, at der nu kun findes én international filterstandard. Det er blevet mere enkelt at sammenligne og købe de rigtige filtre. Den nye standard inddeler desuden filtrene i flere klasser og giver filtrene navne, der fortæller noget om, hvor gode filtrene er til at filtrere bestemte partikler fra luften. Det er der også en kæmpe fordel i, da forskning viser, at sundhedsskadelige partikler i indeklimaet kan være skadelige for vores helbred.

Navngivning af ISO 16890-filterklasser

De nye ISO 16890-filterklasser navngives efter partikelstørrelsen, de testes med efterfulgt af et procenttal.

Et filter kan for eksempel fremover hedde ePM 2,5 65%. Her refererer 2,5 til partikelstørrelsen, filteret er testet med, og procenttallet henviser til, hvor mange procent partikler filteret opfanger i denne størrelse.

Samme filter testet med en anden partikelstørrelse kunne dermed også hedde ePM 1,0 55%

For at give et overblik over hvordan EN779:2012 oversættes til ISO 16890, har vi lavet dette skema.

Ikonerne i skemaet giver et overblik over filterklassernes evne til et filtrere henholdsvis støv, pollen og mikropartikler. Læs mere om de forskellige filterbetegnelser samt partikler længere nede på siden.

Navngivning af ISO 16890-filterklasser

De nye ISO 16890-filterklasser navngives efter partikelstørrelsen, de testes med efterfulgt af et procenttal.

Et filter kan for eksempel fremover hedde ePM 2,5 65%. Her refererer 2,5 til partikelstørrelsen, filteret er testet med, og procenttallet henviser til, hvor mange procent partikler filteret opfanger i denne størrelse.

Samme filter testet med en anden partikelstørrelse kunne dermed også hedde ePM 1,0 55%

For at give et overblik over hvordan EN779:2012 oversættes til ISO 16890, har vi lavet dette skema.

Ikonerne i skemaet giver et overblik over filterklassernes evne til et filtrere henholdsvis støv, pollen og mikropartikler. Læs mere om de forskellige filterbetegnelser samt partikler længere nede på siden.

ISO 16890 vs. EN779:2012

Den største forskel på ISO 16890 og EN779:2012 er, at filtre der testes ved EN779:2012-standarden kun testes op mod én partikelstørrelse – 0,4 µm. Men da de partikler, der findes i luften, ikke har samme størrelse eller form, viser testen ikke det fulde billede af, hvad et filter bliver udsat for i virkeligheden.

Når et ISO 16890-filter derimod testes, er der fokus på at indfange flere forskellige partikelstørrelser i filteret. Der testes altså med forskellige størrelser fra 10 µm og helt ned til 0,3 µm. De tests, der udføres i dag, er langt mere realistiske og virkelighedstro, så du er garanteret, at filteret, du køber, fungerer som forventet og filtrerer farlige partikler væk. Med ISO 16890 kan der altså ikke stilles spørgsmålstegn til kvaliteten, og du er sikret, at filtrene lever op til de internationale normer, der er for test og kvalitet.

Hvad er partikler og hvorfor kan de være farlige?

Helt simpelt forklaret er partikler de bittesmå stoffer, der hvirvler rundt i vores luft. Nogle af dem er naturligt skabte andre kommer fra forurening. Områder med meget trafik, industri og/eller brændeovne er mere udsatte.

Partikler kan overordnet inddeles i 4 kategorier:

Grove partikler: Partikelstørrelse over 10 µm (ePM 10): Støv og snavs.

Mellemgrove partikler: Partikelstørrelse på 2,5 - 10 µm (ePM 2,5 – ePM 10): Mekanisk vejstøv, dækslitage og byggestøv samt naturlige kilder som jordstøv og pollen.

Fine partikler: Partikelstørrelse på 1 - 2,5 µm (ePM 1 – ePM 2,5): Svovldioxid og kvælstofdioxid (NO2) fra motorer og f.eks. kraftværker samt skimmelsvampesporer.

Ultrafine partikler: Partikelstørrelse på under 0,1 µm (PM 0,1): Sodpartikler fra f.eks. brændeovne

Hvorfor er partikler farlige for helbredet?

Det anslås, at over 4.000 danskere årligt dør som en konsekvens af luftforurening. Partikelforurening kan derfor have alvorlige konsekvenser for helbredet.

Effekten af partikelforureningen er dog lettere kompliceret. Det hele afhænger nemlig af partiklens størrelse og form, da der er forskel på, om vi indånder partiklerne, og hvor de bliver afsat i vores luftveje.

Forskere har bevist, at det er de fine- og de ultrafine partikler, der er de farligste – altså dem der er mindre end 2,5 µm. De grovere partikler (over 2,5 µm) bliver fanget af kroppens egen forsvarsmekanismer i f.eks. næsen.

Men de fine- og ultrafine partikler kan trænge gennem forsvarsmekanismerne og sætte sig i luftvejene. Dette kan føre til en forværring af astma, andre lungesygdomme og i værste tilfælde kræft. Hvis partiklerne trænger fra lungerne ind i kredsløbet, kan de desuden sætte sig i blodbanerne og medvirke til åreforkalkning og blodpropper.

De forskellige filtertyper i sortimentet

Standardfilter – G4, grovfilter der tager 75% af de grove partikler.

Pollenfilter – F7, finfilter der udover de grove partikler også tager 55% af finpartiklerne under 1,0 µm og 77% af finpartiklerne mellem 1,0 og 2,5 µm.

SafeAir-filter – F9, finfilter der tager 85% af finpartiklerne under 1,0 µm og alt derover.

Kulfilter – aktivt kul der fjerner lugtgener. Kulfilteret har i sig selv ingen partikelfiltrering og skal bruges i kombination med et partikelfilter.

SafeAirPlus-filter – F9 filter kombineret med et kulfilter.

I dette skema har du en oversigt over de forskellige filtertyper, og hvor mange procent af de forskellige filterstørrelser, de filtrerer fra.

De forskellige filtertyper i sortimentet

Standardfilter – G4, grovfilter der tager 75% af de grove partikler.

Pollenfilter – F7, finfilter der udover de grove partikler også tager 55% af finpartiklerne under 1,0 µm og 77% af finpartiklerne mellem 1,0 og 2,5 µm.

SafeAir-filter – F9, finfilter der tager 85% af finpartiklerne under 1,0 µm og alt derover.

Kulfilter – aktivt kul der fjerner lugtgener. Kulfilteret har i sig selv ingen partikelfiltrering og skal bruges i kombination med et partikelfilter.

SafeAirPlus-filter – F9 filter kombineret med et kulfilter.

I dette skema har du en oversigt over de forskellige filtertyper, og hvor mange procent af de forskellige filterstørrelser, de filtrerer fra.

Er filtrene blevet dyrere med ISO 16890?

Alle vores filtre er testet efter ISO 16890. Det koster ikke ekstra. Det er nemlig vores ansvar at teste og dokumentere vores produkter, og Danfilters interne produktion er omlagt, så vi overholder de gældende krav for ISO 16890. De leverandører, vi bruger, producerer også i henhold til ISO 16890. Når du handler hos os, er du altså sikret filtre af god kvalitet, der er testet efter den internationale standard.

Vores filtre er tydeligt mærket med både EN779:2012 og ISO 16890, så overgangen er nemmere.

Har du yderligere spørgsmål til vores specifikationer eller filterstandarder, er du velkommen til at kontakte vores Kundeservice.