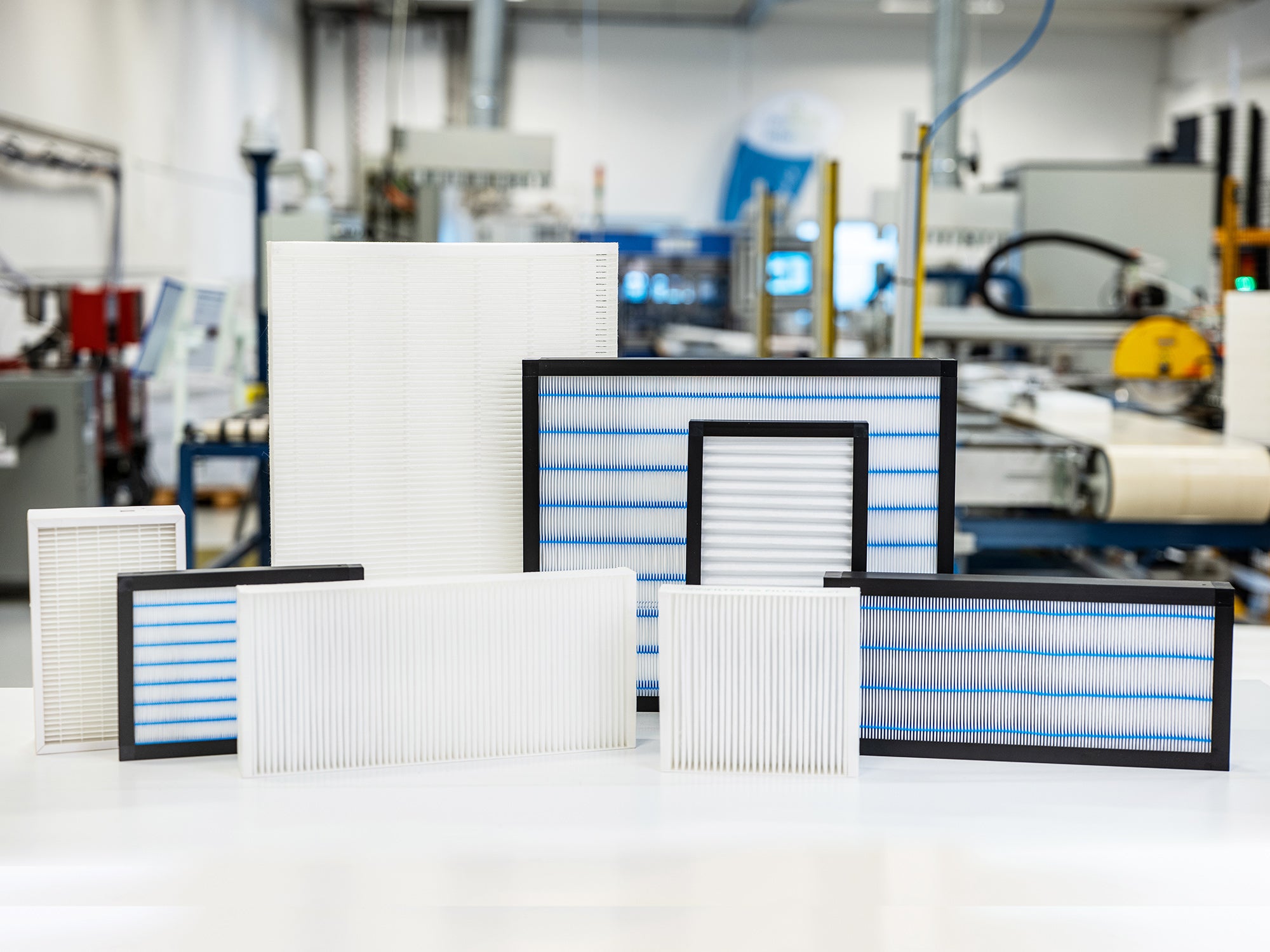

No Glass: Et bedre filtervalg uden glasfiber

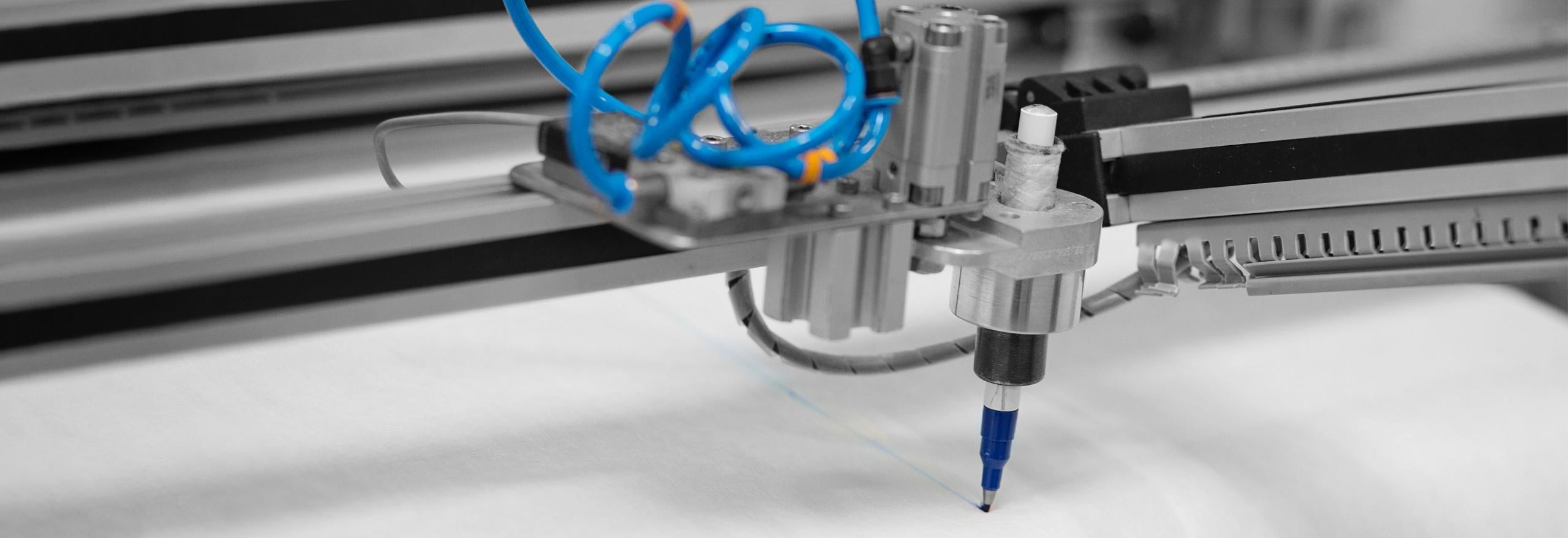

Hos Danfilter anvender vi i stigende grad syntetiske fibre (polyesterbaserede) frem for traditionelle glasfibermaterialer i vores luftfiltre. Denne udvikling er ikke tilfældig, men et resultat af vores fokus på sikkerhed, holdbarhed og miljøvenlighed. "No Glass"-konceptet dækker over filtre, der er produceret uden anvendelse af glasfiber, og det giver en række tekniske og praktiske fordele.

Fordele ved syntetiske (no glass) filtre

- Sikkerhed og arbejdsmiljø: Ingen afgivelse af irriterende glasstår – nemmere og mere sikkert at arbejde med.

- Miljøvenlighed: Polyester kan lettere genvindes og indeholder ingen farlige stoffer.

- Lang levetid: Syntetiske filtre er mere modstandsdygtige over for fugt, deformation og tryktab over tid.

- Konsekvent filtreringsydelse: Takket være stabil fiberstruktur.

- Lavere trykfald: Moderne syntetiske medier har forbedret aerodynamik og kan bidrage til lavere energiforbrug.

No Glass: Et bedre filtervalg uden glasfiber

Hos Danfilter anvender vi i stigende grad syntetiske fibre (polyesterbaserede) frem for traditionelle glasfibermaterialer i vores luftfiltre. Denne udvikling er ikke tilfældig, men et resultat af vores fokus på sikkerhed, holdbarhed og miljøvenlighed. "No Glass"-konceptet dækker over filtre, der er produceret uden anvendelse af glasfiber, og det giver en række tekniske og praktiske fordele.

Fordele ved syntetiske (no glass) filtre

- Sikkerhed og arbejdsmiljø: Ingen afgivelse af irriterende glasstår – nemmere og mere sikkert at arbejde med.

- Miljøvenlighed: Polyester kan lettere genvindes og indeholder ingen farlige stoffer.

- Lang levetid: Syntetiske filtre er mere modstandsdygtige over for fugt, deformation og tryktab over tid.

- Konsekvent filtreringsydelse: Takket være stabil fiberstruktur.

- Lavere trykfald: Moderne syntetiske medier har forbedret aerodynamik og kan bidrage til lavere energiforbrug.

Hvad er forskellen på glasfiber og syntetiske fibre?

Glasfibermaterialer

Glasfibermaterialer anvendes traditionelt i mange filtre pga. deres fine struktur og evne til at tilbageholde partikler. Men de kan afgive mikroskopiske glasstår, som udgør en risiko for hud, øjne og luftveje – både for brugeren og serviceteknikeren. De er desuden ikke biologisk nedbrydelige og kan være svære at bortskaffe miljøansvarligt.

Syntetiske fibre

Syntetiske fibre, typisk fremstillet af polyester, er blødere, mere fleksible og uden sundhedsrisiko ved berøring eller udskiftning. De er lette at håndtere, mere modstandsdygtige over for fugt og mekanisk stress, og de bevarer deres struktur og ydeevne længere over tid.

Et ansvarligt filtervalg

Flere førende producenter i Europa har i dag udfaset glasfiber som standardmateriale i deres luftfiltre – og Danfilter går samme vej. Vi mener, at syntetiske filtre repræsenterer fremtidens løsning, hvor effektivitet, holdbarhed og ansvarlighed går hånd i hånd.

Vores "no glass"-filtre kan anvendes i både komfortventilation, industri, kontorer, offentlige bygninger og steder med skærpede krav til hygiejne og brugersikkerhed.

Kontakt os og hør mere om vores glasfiberfrie filterløsninger – og hvordan du kan skifte til en sundere, sikrere og mere fremtidssikret filtrering.